Business connections are getting more and more complex in our modern IT-driven world. Production capabilities are impressive nowadays. However, this doesn’t create complications if the proper supply chain management is applied.

As the chain grows and becomes multi-stage, a vast amount of third-party agents and middlemen enter the scene. The issue of honesty, transparency, and overall efficiency arises. This is where a distributed ledger comes in handy.

Let’s discover the most significant advantages of blockchain technology in supply chain management and figure out how it can change our understanding of the supply chain ecosystems.

The major challenges modern supply chain systems face

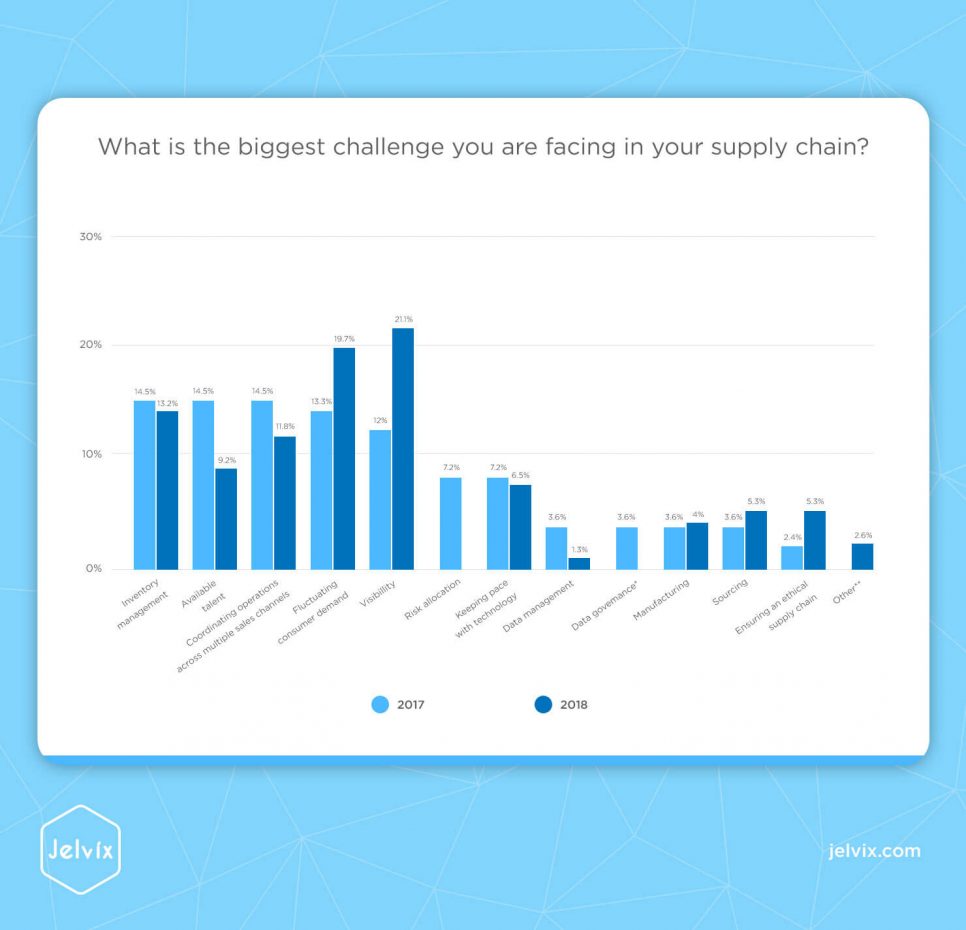

As our society and technology evolve, logistics networks are reporting new issues they suffer from the most. Have a look at the chart of the biggest challenges businesses face in the last 2 years:

As you can see, talent availability has become less of an issue, while the visibility and the consumer demand fluctuation are the most pressing problems of the companies involved in supply chains these days. This demonstrates that conventional data management approaches are getting less and less efficient.

Let’s find out how a distributed ledger addresses the mentioned issues and consider several case studies to have a comprehensive understanding of how this technology can make logistics networks a better place.

DLT in supply chain: the most substantial benefits

The blockchain technology has several significant edges over the conventional management systems:

- Network decentralization;

- Data transparency;

- Processes acceleration;

- Cost reduction.

Let’s consider each one in detail to understand how this affects logistics networks’ performance.

Network decentralization: no sole data owner

The current centralized supply chain scheme implies that the better part of data is under the control of one company. Unfortunately, this brings mistrust sometimes, as nothing but ethical concerns stop companies from falsifying data for profit.

Integrating blockchain in supply chain solves the issue. Thanks to the decentralized nature of the distributed ledger, this technology can boast of a trustworthy way to store data. The fraud chances are virtually zero, as long as data is equally allocated amongst users of the ledger. It means no one can perform an unsanctioned data modification. This breaks the monopolist limitations and creates room for improvement in supply chain management.

Data transparency: everyone can track everything

Process transparency is an essential aspect of trustful partner relations. You can hardly deny the existence of a transparency issue in the supply chain nowadays. Implementing blockchain in a logistics network means every member of the network can now access any available piece of data. This brings us to the level where every single transaction stays transparent and cannot be removed.

This is an indisputable advantage of the blockchain technology over the conventional approaches. DLT helps to mitigate business relations tension and establishes partner trust. This is what most supply chains lack these days.

Processes acceleration: less manual approvals – faster workflow

Blockchain tech allows logistics networks to focus on what matters and let the DLT handle all the verification and approval mess. Traditional supply chains rely on countless manual transaction validations and endless documentation turnover. This issue is amongst the most severe disadvantages of conventional systems. Fortunately, blockchain addresses it as well.

The majority of verification processes in DLT is automatic. This technology eliminates mistakes, simply doesn’t allow performing a forbidden transaction and rejects all unsanctioned network mutations. The self-validation feature of the blockchain makes supply chain management a clear and transparent process.

Cost reduction: universal solution is cost-effective

The last but not the least, the cost-effectiveness of the distributed ledger technology is due to its architecture and scalability. Consider the following situation: a successful automotive supply chain grows and increases turnover. Now, the car parts supplier and the manufacturer store their data in their private databases, because the traditional data storage is vulnerable to attacks and fraud. What can go wrong?

You see, the dependency between the business scale and data volumes is non-linear. Medium-sized and large enterprises of this market sector can store up to hundreds of billions of data entries in their main databases. You can imagine how much it can cost to support these systems separately and integrate them.

As always, a distributed ledger has some alternative to offer. The blockchain technology makes it possible to create a shared network for order management purposes. This is where it gets exciting: the data exchange becomes lightning-fast and virtually error-free. Such improvements can substantially boost the profits of an automotive assembly department or the entire facility.

Use of blockchain in supply chain management: use cases

Now that we have discovered the core edges of the DLT use in the supply chain, let’s figure out how we can implement them into the real-world cases.

Coffee supply chain: a complex system behind a sip of your morning energy

Every single cup of coffee on your table is the result of thousands of connections all over the world. The most burning concern of the coffee supply chain is the remoteness of the supplier locations. As these flavorful beans grow in the developing areas, it gets rather complicated to control the product quality. Many coffee supply chains report abuse cases and are in desperate need to take this aspect under control.

Now, how can blockchain change something? Here’s the thing: this logistics segment craves for data transparency. As soon as these supply chains receive a way to make their data clear and trustful, the prosperity of coffee logistics network will begin. Here are the benefits of using blockchain in the coffee chain supply:

- Data concerning the source of beans;

- Fair deals with the producers;

- Timely and verified coffee supply.

Learn more about the main stages of product development lifecycle to build a sustainable product.

Automotive supply chain: a sophisticated supply chain under your hood

Multi-vendor production and management are one of the most powerful market segment differentiators for Automotive. Production facilities release modern cars you are used to seeing nowadays by assembling pieces from numerous car-parts suppliers. This creates an exceedingly high risk of counterfeit and low-quality products getting on the market. And we don’t want our airbag to fail when it’s needed, do we?

DLT implementation brings to life a digital representation of every single part produced by suppliers. This leads to the following improvements:

- Data transparency actually nullifies the counterfeit production;

- Order approval and validation is automatic, which leads to costs reduction;

- Shared data source. All the chain supply elements under one network would mean unlimited optimization opportunities and production acceleration potential.

Need a qualified team?

Extend your development capacity with the dedicated team of professionals.