In one of his famous quotes, Bill Gates, the founder and former CEO of Microsoft, said, “A rule of thumb is that a lousy process will consume ten times as many hours as the work itself requires.” The idea behind this is that the time spent at each business process will have a massive impact on your organization’s final output.

An organization that optimizes its processes using suitable methodologies will spend way less time and money on specific business processes than one that gets into doing stuff without optimizing. According to one of the studies done about business process optimization, 65% of organizations that took this survey agreed that business process management systems and technologies helped them improve efficiency.

This article is for you if are keen to learn more about how to implement business process improvement. We will share everything you need to know about business process improvement, the methodologies you can use, and some of the common examples of business process improvement.

Let’s dive in!

Business Process Improvement Methodologies

Over the years, several methodologies have been developed, and all of them were invented to make business processes more efficient. The first wave was in the 1980s when software and IT were still in the baby stages. The second wave of business process improvement happened in the early 1990s. It was during this wave that most of the methodologies discussed in this article were introduced to the market, thanks to available software and IT tools.

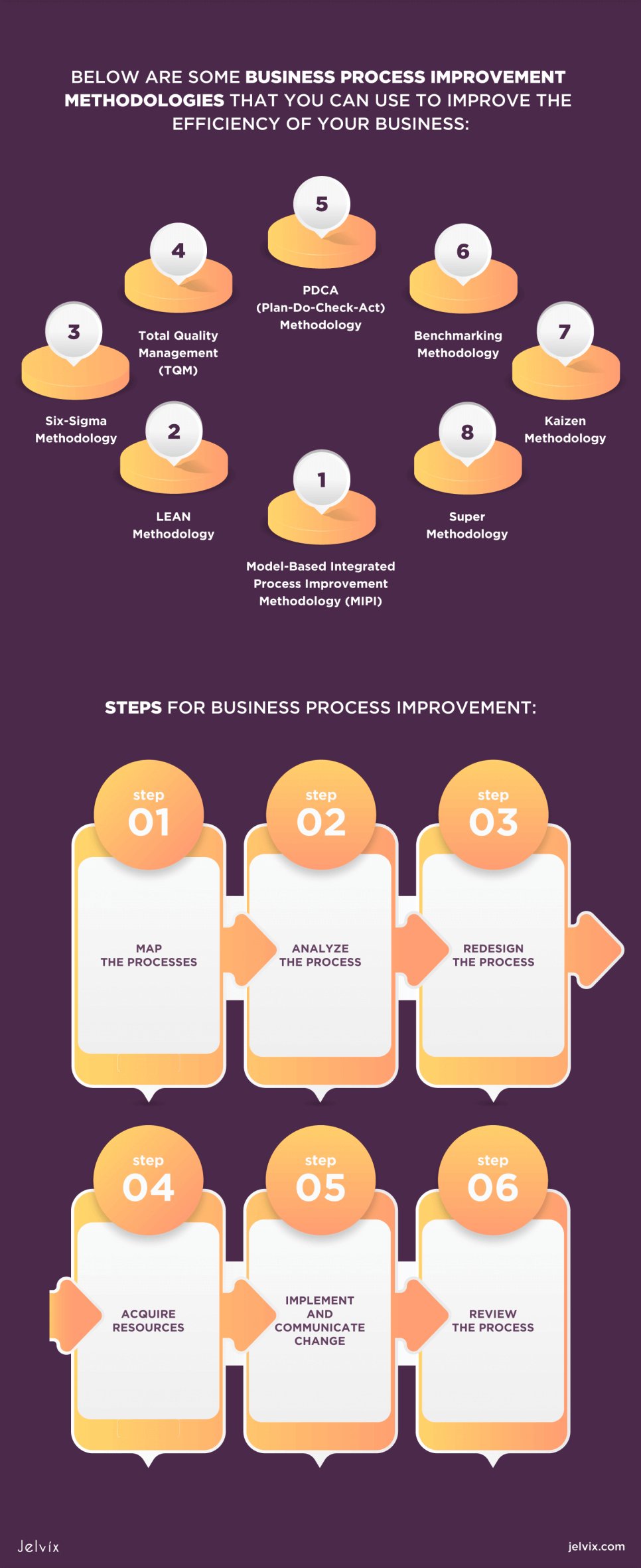

Below are some business process improvement methodologies that you can use to improve the efficiency of your business. The choice of which method you go with should largely depend on the kind of work your organization does on a day-to-day basis.

-

Model-Based Integrated Process Improvement Methodology (MIPI)

This methodology mainly involves determining what to do and how to do it. This methodology aims to assess your organization’s needs and then highlight the bottlenecks limiting you from meeting those needs. With MIPI, you will have to dig deep into the details of all the existing business processes and redesign them to improve their efficiency.

Model-Based Integrated Process Improvement Methodology is implemented using these seven steps:

- Determining the needs of your business

- Assessing and understanding the existing processes

- Analyzing and modeling the processes

- Mapping and redesigning the processes

- Implementing the new process that you have designed above

- Assessing the impact of the new process and methodology

- Doing a review of the new processes implemented

-

LEAN Methodology

This methodology of business process improvement was introduced to the world by Toyota after the second world war. Its main aim is to eliminate waste of time and other resources during the production process. That is why lean manufacturing is also referred to as Just-in-time manufacturing.

With this methodology, Toyota fused the manufacturing techniques of Henry Ford and the statistical quality control ideas of Edwards. The Lean methodology was also adopted by other industries, including the ones not into manufacturing. Some of the famous companies that adopted lean manufacturing techniques include; Intel, Nike, Caterpillar Inc, etc.

The main issues that the Lean methodology addressed include;

- Production bottlenecks

- Reducing imbalances in the production quantities

- Reducing transportation inefficiencies

- Reducing inventory errors

- Minimizing product defects

- And minimizing any other form of wastage

-

Super Methodology

This methodology mainly focuses on improving the business processes of small and medium-sized enterprises. It uses the 5-step improvement strategy that is aimed at improving the overall productivity of the organization. The five steps for implementing this strategy include:

- Process selection, which involves determining processes with bottlenecks

- Understanding each process and the variety of components involved

- Process measurement, which consists of using KPIs to evaluate the effectiveness of the process

- Executing the new process based on the KPIs

- Reviewing the new process and comparing its outcomes with the previous.

-

Benchmarking Methodology

The idea behind this methodology is choosing a business that you can use as a “gold standard” and then adapting their ideas and methods of implementing various business processes. The ideal company you can choose to be your “gold standard” is one within your industry. For instance, if you are in the software industry, you can use Microsoft as your benchmark and adopt some of the ideas and strategies they use to implement their business processes.

With the benchmarking methodology, you may not necessarily have to adopt everything about the company that you are using as your benchmark. You may choose to adopt only their manufacturing process or their management strategies.

Some examples of companies that use this methodology are GM and Ford, which adopted the manufacturing strategies used by Toyota and Honda. These two Japanese companies had adopted the lean methodology to make their car engines more fuel-efficient, and they successfully achieved that, at least in the short run. So, Ford and GM had to adopt these two as their benchmark to improve the efficiency of their car engines.

-

PDCA (Plan-Do-Check-Act) Methodology

Shewhart developed this business process improvement methodology at Western Electric. PDCA focuses on continuous improvement of business processes and checking the effectiveness of each change through feedback. Below are more details of all the four stages of this methodology:

- Plan. At this stage, planning is made to implement the changes that have been identified to improve the productivity and efficiency of specific business processes.

- Do. This stage involves the implementation of the suggested changes. While implementing the changes, it is better to start with a few and then monitor their impact before implementing more.

- Check. This stage is all about assessing the impact of implemented changes using quantifiable metrics like the time and money saved by the new process.

- Act. After testing the impact of changes, the next stage is acting and driving those changes forward in the organization. If the changes haven’t yielded the results you expected, adopt new changes and take them through the same test right from the first stage.

-

Six-Sigma Methodology

This business process improvement methodology focuses on eliminating errors and any defects in the outputs by emphasizing them that affect customer satisfaction. Motorola introduced this methodology in 1986 to minimize defects and cycle time during production. Here is a fun Video elaborating how the Six-Sigma Methodology is implemented.

The Six-Sigma methodology mainly uses two approaches: the Design Measure Analyze Improve Control (DMAIC) approach and the Design Measure Analyze Improve Verify approach (DMAIV).

-

Kaizen Methodology

In Japanese, the word Kaizen means gradual improvement, so Kaizen methodology is all about making incremental steps in improving the identified business process that needs your attention. With this methodology, the goal is to take smaller steps, which eventually create a significant impact in the long term.

The Kaizen methodology’s five fundamental elements include teamwork, personal discipline, improved morale, quality circles, and suggestions for improvement. Some of the popular brands that have used the Kaizen methodology include Ford, Herman Miller, Nestle, and Lockheed Martin.

-

Total Quality Management (TQM)

TQM is a business process improvement methodology that is ideal for businesses operating in highly dynamic industries. This methodology involves using systems, tools, and techniques to adapt to the changing customer demands. With TQM, all departments work hand in hand to constantly improve their output quality to meet your customers’ dynamic needs.

Western Electric Company was the first to implement the TQM methodology of business process improvement during the 20th century. This methodology was later adopted by several popular companies worldwide, including Philips Semiconductor, Motorola, and SGL carbon.

Steps for Business Process Improvement

-

Map the Processes

After identifying the process in your business that you want to improve, take time and document all the steps involved in that process. To ensure you don’t leave out anything, you should do this step with the guidance of your team’s actual members who execute this process on a day-to-day basis. Using schematic diagrams like flow charts will make it easier to visualize all the steps involved in the process you intend to improve.

-

Analyze the Process

Now, when all the steps of the process are mapped out on a flow chart, analyze each step and note the problems they face. At this stage, all stakeholders involved in each of the steps mapped out need to actively contribute if the aim is to define all the problems clearly.

Some of the parameters that you need to look at while analyzing each step include the following:

- Difficulty in executing tasks at each step

- The time for completing each of the tasks

- Costs involved at each step

- The level of frustration that clients or team members get while each step is being executed

-

Redesign the Process

After analyzing each step involved in executing a specific process and identifying each step’s problem, the next thing is devising solutions for each step. At this level, you must consider all the issues identified and ensure solutions are put in place for each problem. Brainstorming with your team is one of the best ways to put ideas together to address the issues faced at each step.

Make sure to give your attention to all the suggested ideas, no matter their feasibility and costs involved in implementing them. You can later narrow down to the most practical solutions your business can implement with available resources. Choosing the best solution will require you to do an impact analysis, risk analysis, a failure mode, and effects analysis on each of the suggested ideas.

After thoroughly analyzing each of the suggested solutions, you can now redesign the steps while considering the new ideas you have come up with. It would be best to redraw your flow chart with all the new steps your team has agreed to for easier visualization.

-

Acquire Resources

The suggested changes you need to implement in the business process you want to improve will require resources. Most of the improvements may require buying new equipment or software to make your team more efficient at executing the steps challenging to handle initially.

For this step to be successful, the C-level managers responsible for allocating resources need to understand the benefits each of the extra investments will bring to the table.

-

Implement and Communicate Change

Once resources are availed, it is now time to implement all the feasible new steps suggested by the team. You will have to communicate with all the concerned stakeholders to make them get ready for these changes. For instance, there might be a need to recruit new team members or train the existing ones to adopt some of the technologies that will make the processes more efficient.

Most of the time, humans don’t easily adjust to new changes, more so if they bring immediate discomfort. The best way to deal with this is by implementing these changes in an incremental manner to ensure your team gets used to a particular change before rolling out the next.

-

Review the Process

After implementing all the changes made in executing a specific business process, you need to review and get feedback regarding the impact. It would be best if you had metrics that you can use to compare the impact of the new process design with the previous one. For instance, if a particular step used to take a lot of time and money to execute, find out how much time and money the newly designed process saves at that specific stage.

If you discover problems while implementing some new steps, new ideas for solving these problems should be suggested, tested, and implemented. It should also be noted that some of the changes may take time for their impact to be felt. This scenario is common with changes that require your team to adopt new skills to implement them.

Learn more about the main stages of product development lifecycle to build a sustainable product.

Business process improvement examples

Below are some of the best practical examples of Business Process Improvement.

-

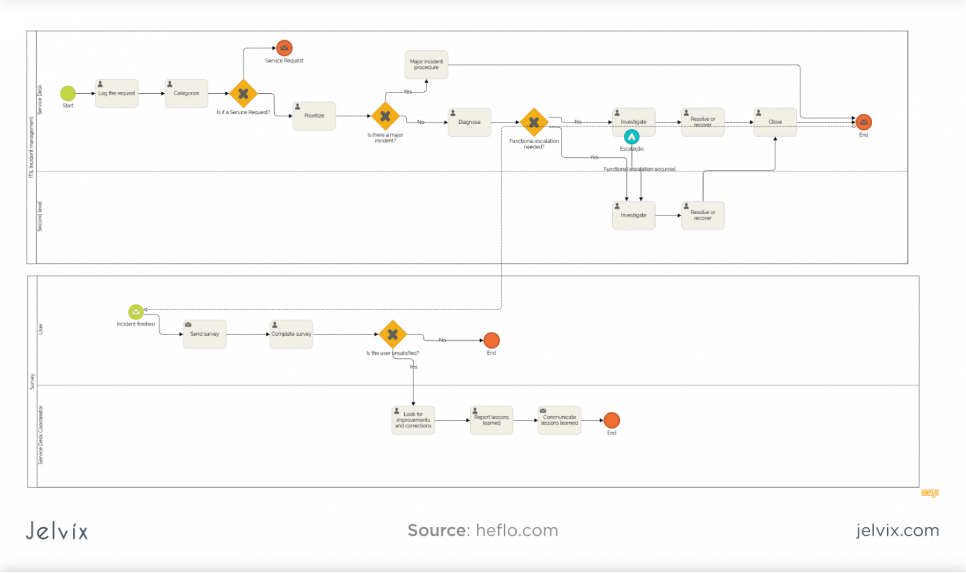

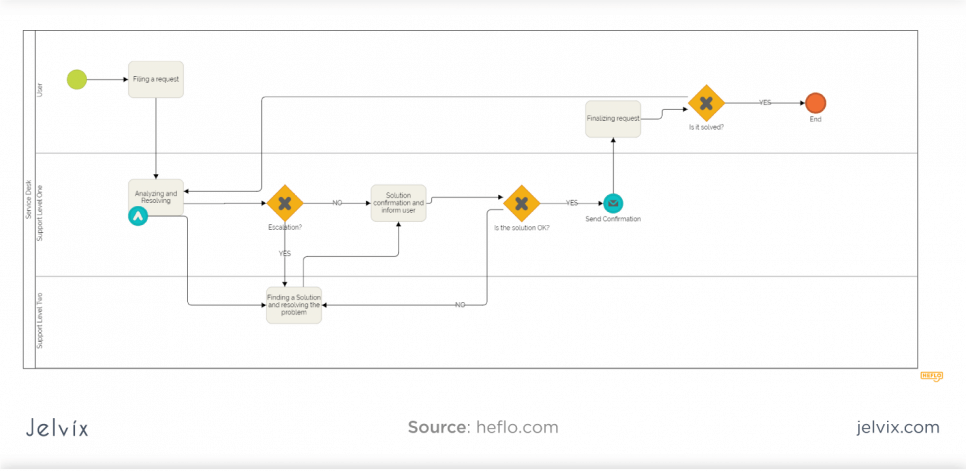

ITIL Incident Management

The main goal of improving the incident management process is to fix any anomaly as soon as possible and minimize its impact on the rest of the business operations. Below is a flow chart showing the details of all steps involved in incident management and how to improve them to make the process more efficient.

-

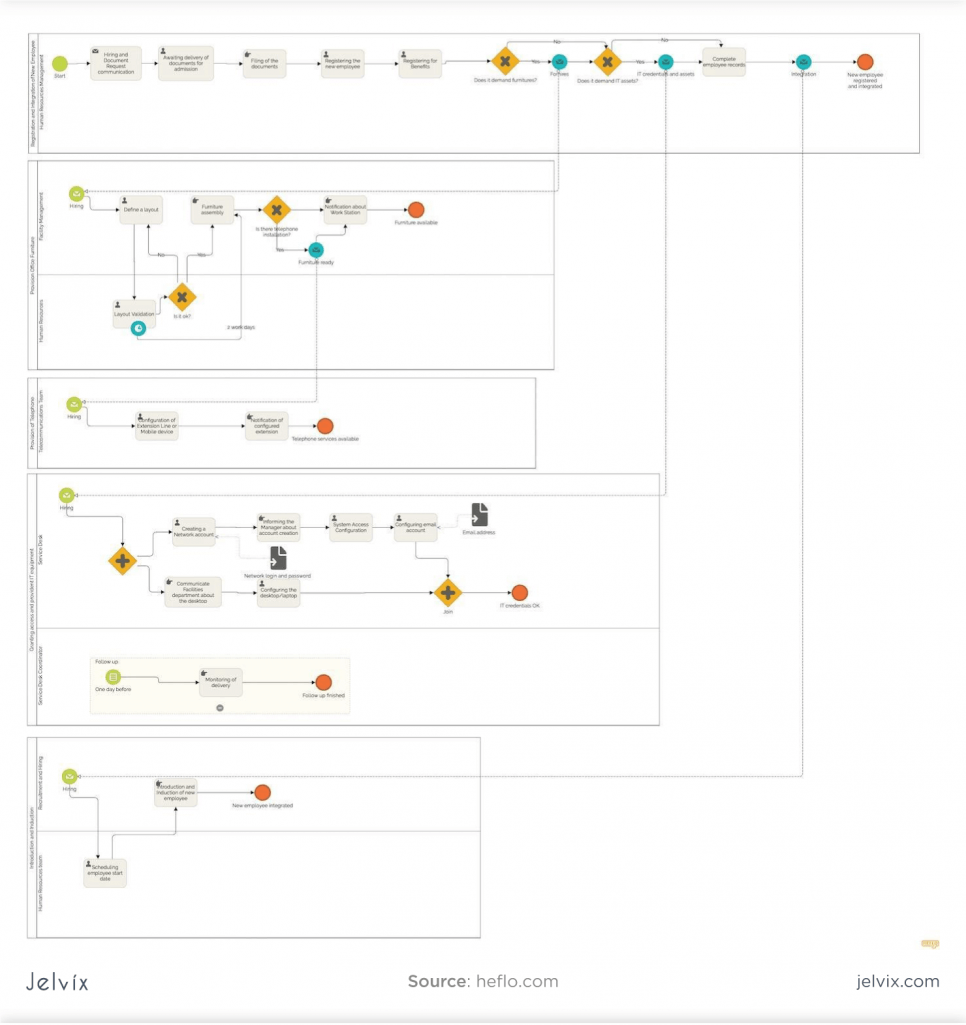

Employee Registration and Onboarding

The process of employee registration and onboarding involves training and giving all the necessary information to newly employed workers to ensure they quickly adapt to the new environment and the job. The diagram below shows the steps involved in implementing and improving this process.

-

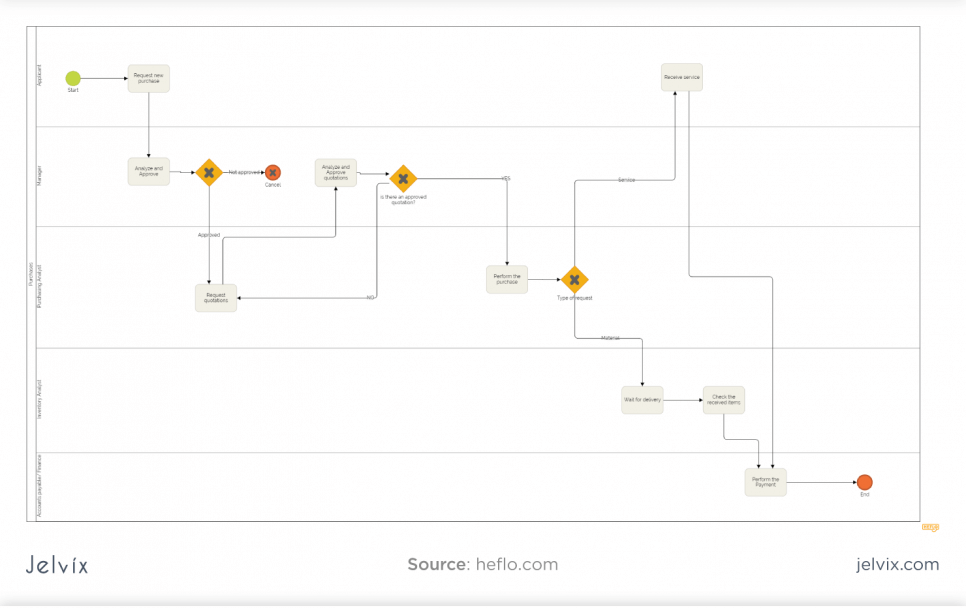

Procurement Process

The procurement process involves all the necessary activities done while purchasing new items into the business. The flowchart below shows the most common procurement steps for a typical business.

This step usually involves all activities done while managing IT-related issues that your customer or employees could be facing. Below is a flowchart indicating the steps involved, so you can base on these to make your changes.

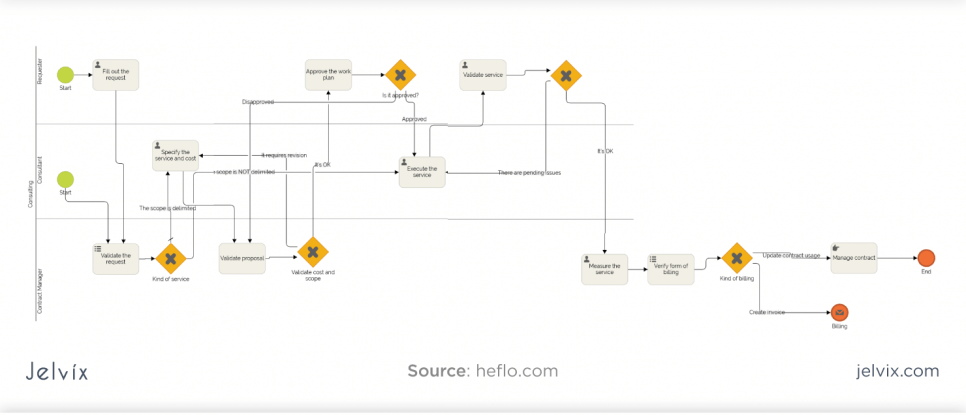

- Consulting Services

For most consulting services, the client requests what he needs the consultant to help them with. The consultant will then render a service based on the request made by their client. This process involves lots of steps, just like in the flow chart below.

-

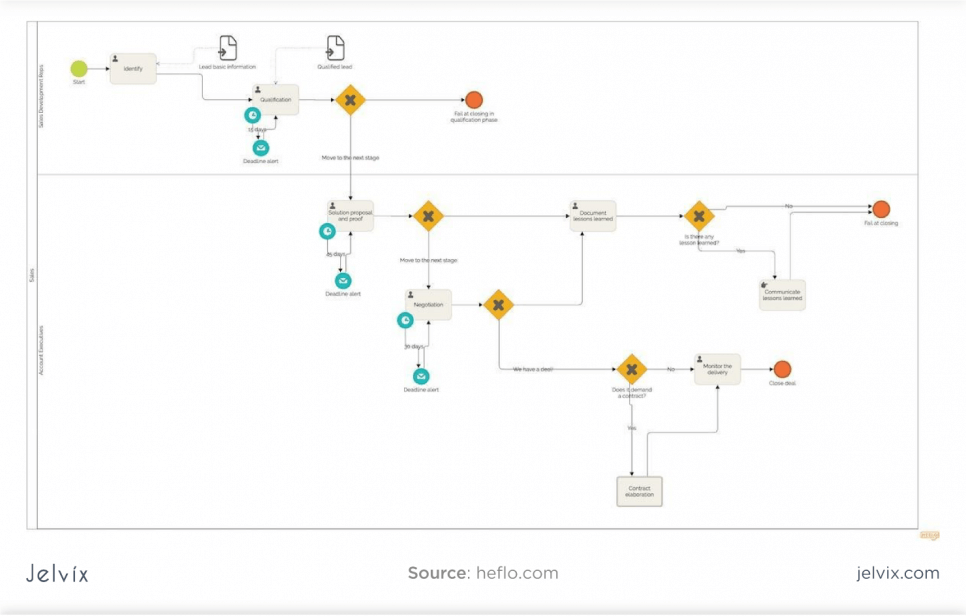

Sales

The sales process involves all the direct activities done during the sale of goods or services. The flowchart below provides details of all the typical steps involved during a sales process.

-

Non-Compliance

Effectively handling non-compliance is a crucial process for any business that wants to improve its efficiency and reputation in the market. The flowchart below shows all the typical steps involved while handling this process.

Final Thoughts

We have looked at the eight business process improvement methodologies that you can use to increase your business’s productivity and efficiency. The common denominator for all the methodologies covered is identifying the problems with current processes and coming up with solutions to fix them.

As a business, you can sit down with your team and choose the ideal methodology that suits the kind of work you do. Some of the methodologies like the lean methodology can be applied in almost all business types. However, you may have to make some tweaks to make it work in your business setup.

Keep in mind that implementing these process improvements will require investing more resources, especially during the early stages when radical changes are made. So, you may have to plan for these resources ahead of time.

Need a qualified team?

Reach top talent pool to handle end-to-end delivery of your project.