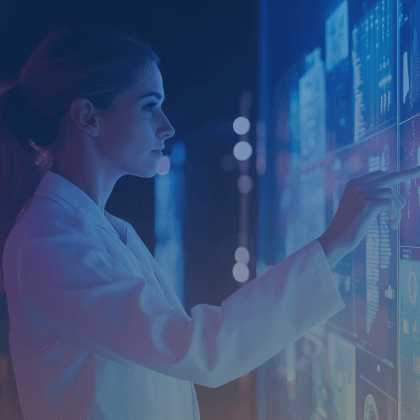

Steep development of technologies and automation of manufacturing have made interaction with machines a part of our everyday routine. With 90% of information transmitted to our brain being visual, it becomes apparent that the best way to manage interactions between a human and a machine is by using visual representations.

That is exactly where a human-machine interface comes to the rescue. It serves as a medium that allows for seamless control and communication between the systems and human operators. Throughout their history, human-machine interfaces have undergone the evolution from panels with basic push buttons or switches to the latest touch-screen displays.

Yet, the industry that defines how people communicate with machines is still advancing. The growing demand for smart automation tools and Industry 4.0 tendencies are the central factors influencing the HMI transformation and development.

According to the MarketsandMarkets research, the human-machine interface market is anticipated to reach $5.6 billion by 2025 from $4.3 billion in 2020, growing at a CAGR of 5.2%. Moreover, the ability of HMI systems to improve the effectiveness of production processes is only going to boost the demand for the development of HMI solutions in the mentioned period.

In this article, we are going to take a closer look at the HMI meaning, discover where it can be implemented, how it works, and why it is beneficial for businesses. And, of course, we will get a glimpse of what the future holds for this industry.

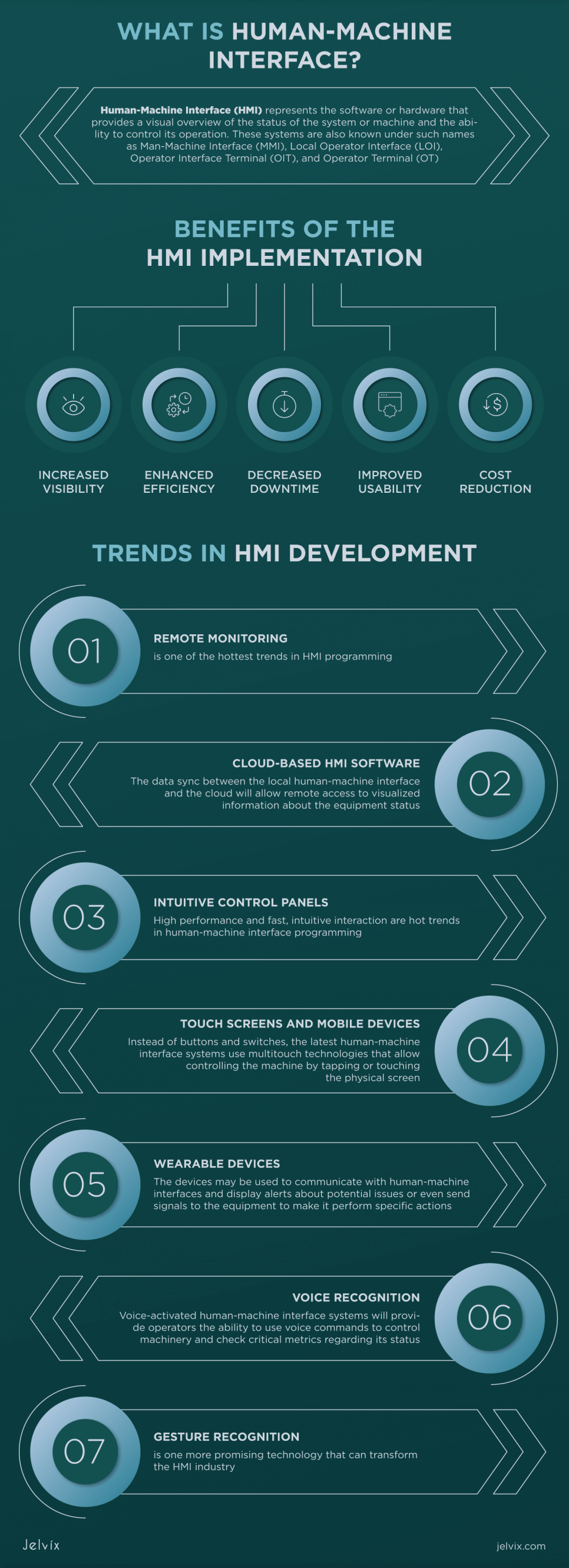

What is HMI?

Human-Machine Interface (HMI) represents the software or hardware that provides a visual overview of the status of the system or machine and the ability to control its operation. These systems are also known under such names as Man-Machine Interface (MMI), Local Operator Interface (LOI), Operator Interface Terminal (OIT), and Operator Terminal (OT).

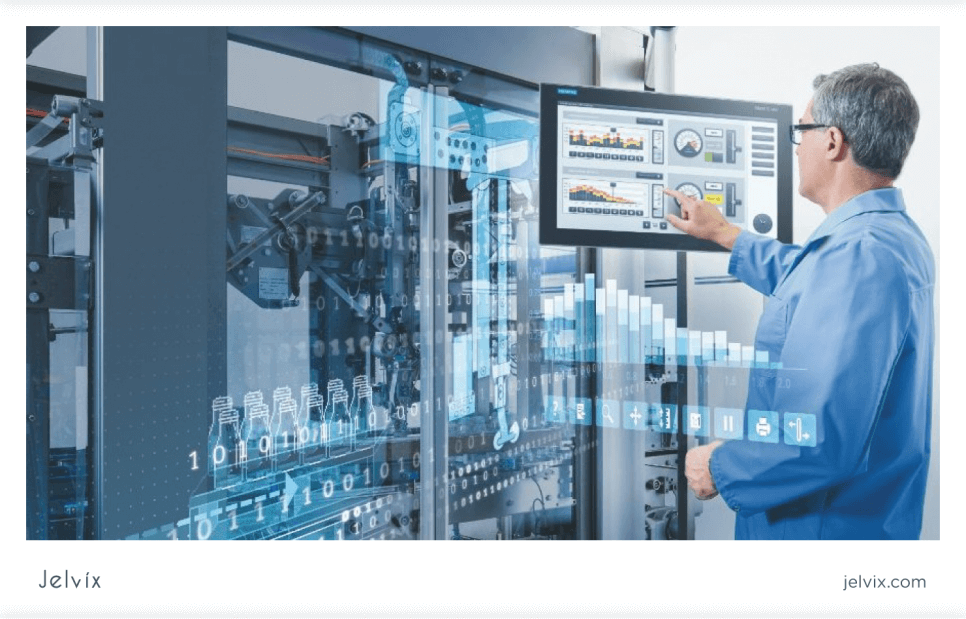

In theory, the term “human-machine interface” may be used to describe any screen used by a person to communicate and control the device. Yet, for the most part, it is commonly applied to characterize touch screen displays built in the machinery, tablets, or terminals positioned as stand-alone that are utilized in the industrial surroundings.

As a rule, the information in the human-machine interface is displayed in a graphical form. The HMI systems use various icons, sounds, pictures, and colors to illustrate machinery’s current status and operating conditions.

Apart from allowing to monitor the state of the processes in industrial environments, the HMI software provides the ability to modify the control settings, change operating parameters of the machine and modify the process sequences in case of emergencies. It can also depict the history data and reports to the authorized operators, managers, administrators, etc.

Since the human-machine interface systems are mostly used in industrial settings, they have to withstand such environments. Therefore, they are usually designed to resist water, dust, moisture, extremely high or low temperatures, and even dangerous chemicals.

How does HMI work?

The complexity of the human-machine interface is directly proportional to the level of complexity of the machinery or systems it is supposed to control. However, this factor may as well depend on how the business plans to utilize it.

The human-machine interface system may be either centered around only one function, for example, to monitor the current status of some process in the machine, or used to perform multiple actions, including the control of equipment and keeping track of its operations.

The HMIs work together with programmable logic controllers (PLCs) and a set of input and output sensors to collect and show data about the specific events based on the pre-defined criteria of the given machine. They can also be used to perform technical operations, involving changing the parameters of production (speed, temperature, etc.) and turning machines on/off.

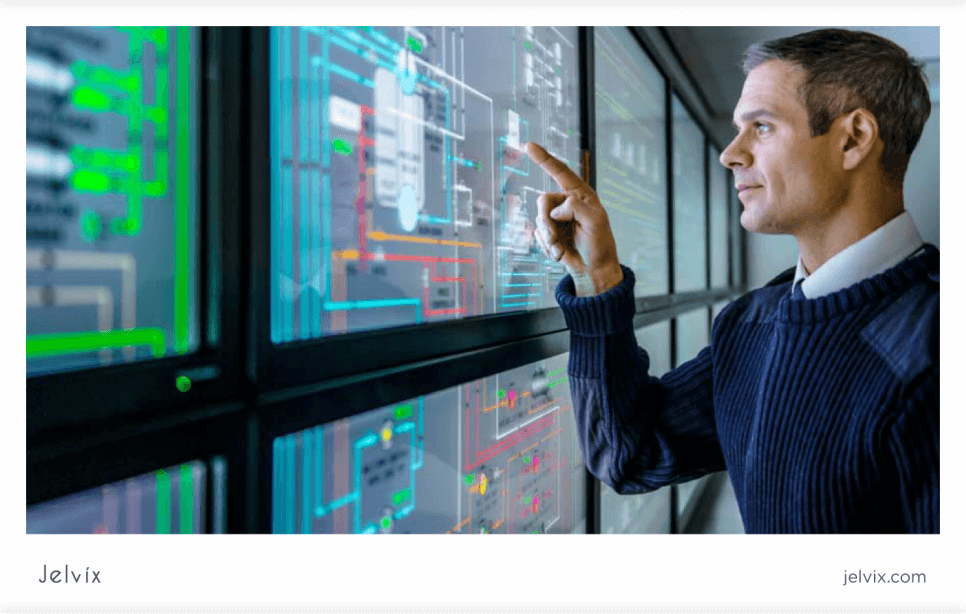

Modern human-machine interface systems provide the ability to centralize information for operators. With this software in place, the operators can view and easily interpret the data displayed in graphs and charts regarding the state and performance of the equipment in an intuitive console.

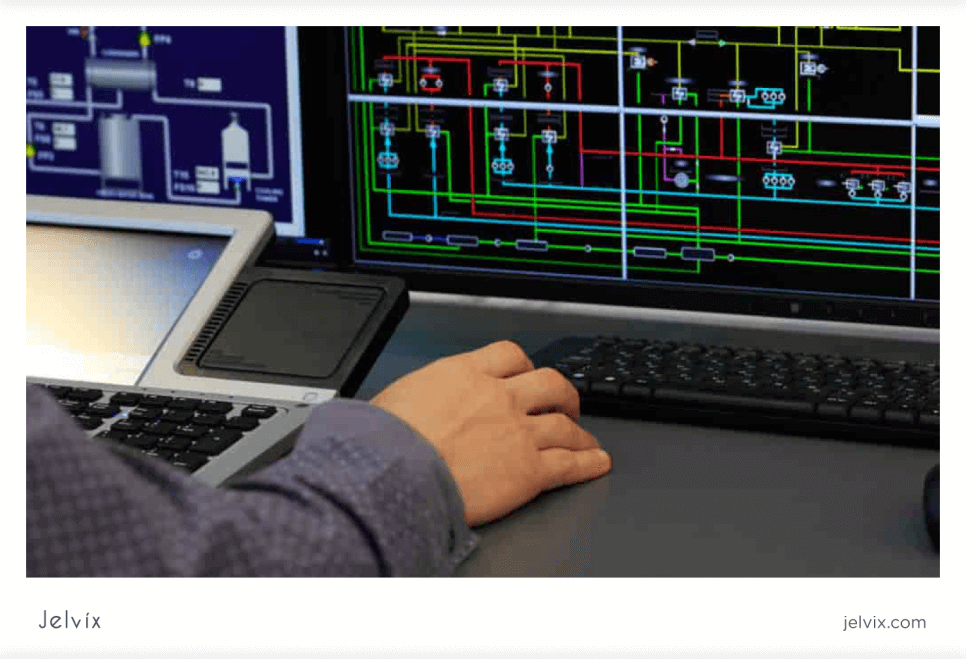

Aside from that, the human-machine interface provides the ability to view and manage alarms, log data that can be used for further process optimization, and communicate with SCADA systems.

In simple terms, it brings transparency into the plant’s operations, allows human operators to handle issues instantly if needed, and increases the productivity of the equipment from a single console.

However, things haven’t always been that way. Prior to the emergence of the HMI software, the operators had to watch over the machinery and check its state by physically approaching each piece of equipment and recording the results on paper.

This process was extremely prone to human errors and sometimes even resulted in financial loss due to the employees’ mistakes that were not noticed in time.

Serving as a centralized source of real-time data, the human-machine interface system substitutes this ineffective practice and eliminates the risks of downtimes. It lets the operators quickly adjust to the changing circumstances and make the relevant changes to operations faster and easier.

Where can Human-Machine Interfaces be implemented?

These days, there is hardly an industry that doesn’t take advantage of HMI technology. Moreover, it’s also used by a bulk of other companies that deal with human-machine interaction to optimize and streamline their industrial operations.

The industries that are actively implementing the HMI systems into their workflows include manufacturing, energy, oil and gas, power, recycling, food and beverage, water and wastewater, transportation, pharmaceutical and biotech sector, and many others.

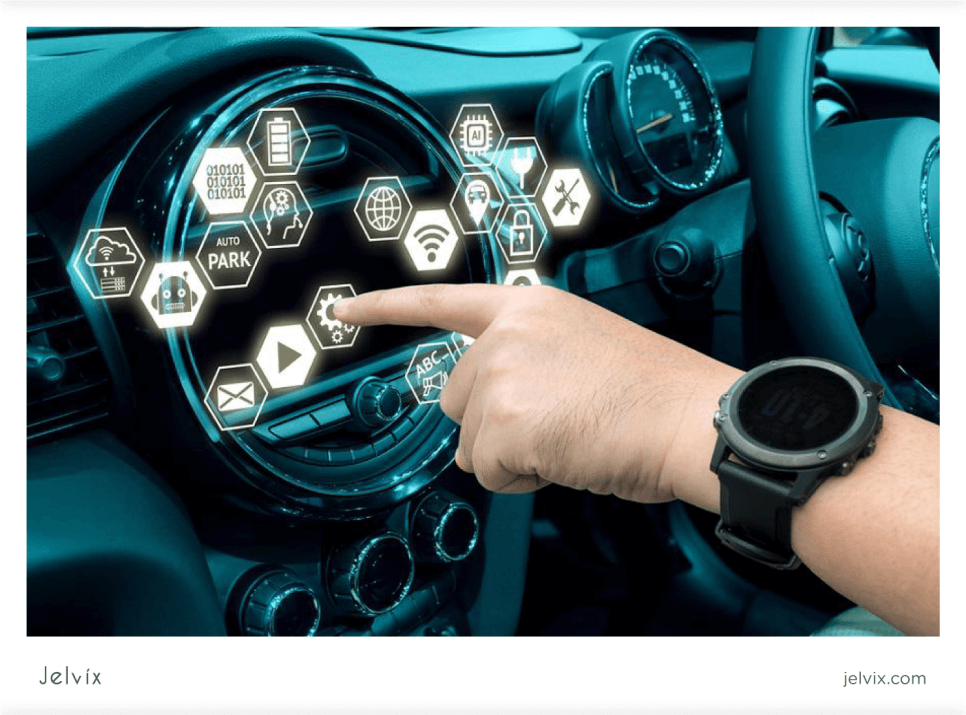

The growing speed of Industry 4.0 and the Industrial Internet of Things (IIoT) advancements are making HMI technology even easier to implement and more widely used. All of this makes it possible for technical professionals to turn smartphones and smartwatches into a sort of mobile or wearable HMIs, which, in turn, increases the accessibility of data.

Benefits of the HMI implementation

The implementation of HMI software provides a wide range of benefits for organizations, including:

Increased visibility

A well-designed human-machine interface system helps to bring more visibility to operations within the organization. By providing highly intuitive dashboards, the system centralizes the data on how the equipment or machine is performing within a single place.

Moreover, the cloud-based HMI may also enable users to access this information remotely. In this way, the employees become more productive, do not miss important alerts, and respond to them faster.

Enhanced efficiency

The human-machine interface system provides access to real-time data about the machines. Having this information at hand, the employees can use it to keep track of the production processes and adapt to the constant demand changes.

As a rule, HMI platforms usually display analytical information that may help organizations define the strong and weak points of their processes and improve the latter in a timely manner. The analytical data may also aid in reducing manufacturing costs and increasing profit margins.

Decreased downtime

Another considerable advantage of the HMI software is its alarming functionality. The alerts shown on a centralized dashboard provide detailed descriptions of the issues that give the ability to locate the malfunctioning equipment quickly and aid in its troubleshooting.

All of this allows employees to eliminate the risks of downtimes and prevent the situations when the issue reaches the emergency level. A thorough analysis of the data about the performance of the machinery can also aid in identifying early signs of mechanical issues. It can be used to solve such problems before they affect the performance negatively.

Improved usability

With a reliable human-machine interface system in place, it becomes easier for the employees to monitor the performance of the facility and control machinery. The data gathered by the software is presented in a visual manner using easy to comprehend and interpret graphs and charts.

In addition, HMIs help with security issues. The operators don’t have to approach dangerous equipment to check its performance. All processes can be controlled from the unified location in real-time.

Cost reduction

The HMI software can also reduce operating expenses. It significantly decreases the number of extra selectors, pushbuttons, cables, indicator light consoles, and panels that have to be installed for every single piece of equipment.

The system allows businesses to replace a lot of the mentioned above things with a centralized console that will be used to control all the equipment.

The difference between HMI and SCADA

Supervisory Control and Data Acquisition (SCADA) and Human Machine Interface (HMI) are closely intertwined terms that are often confused. Although the systems work together, they are not the same in terms of their purpose and functions.

A SCADA system is the main control system of the factory that encompasses other systems such as PLCs, sensors, and RTUs. Its major functions include collecting and recording data, and controlling the machinery operations (in some cases even automatically).

On the contrary, an HMI represents only the interface used to communicate with SCADA, other systems, or the machine itself. Unlike SCADA, it does not collect information; its main function is to display it in an intuitive dashboard.

Both systems are inconceivable without each other. While the SCADA system gathers data needed to control the equipment, the HMI displays it to the user and allows operators to decide how this equipment should perform. In other words, SCADA is the system that performs in the background, while HMI is the medium used by operators to interact with the machinery.

Considerations for designing Human-Machine Interface systems

People interact with HMI systems on a daily basis. Therefore, the design of the human-machine interface is one of the central factors contributing to its ease of use and intuitiveness. Our experts differentiate several key design points that should be considered in HMI programming:

Know your user

In many cases, complex HMI systems contain multiple screens with separate interfaces for different types of users with different types of access. Before dipping your toes in designing the HMI software, think about the people that are going to use it. Determine what kind of information the user would like to know and which machine functions they would like to control.

Visibility

When it comes to human-machine interface programming, it is important not to overstuff the interface with unnecessary data and make the essential information easy to find. In order to make the important data more eye-catching for the user, you may use:

- color-coding to depict the process statuses;

- animation for alarm messages to catch the user’s attention;

- navigational links to provide quick access to the related information or functions.

Simplicity

Another factor influencing the usability of the HMIs is their simplicity and intuitiveness. The more straightforward and uncluttered the interface is, the less training it will require and the higher user adoption rates it will have.

Consistency

In case you are designing complex HMI software (that includes several interfaces and screens), you should remember that displays, actions, and layouts should be consistent for every single screen.

Do not change the positions of navigational buttons or vary the color codes for status displays throughout the system. Otherwise, it may lead to user confusion and critical human errors.

Trends in HMI development

Industry 4.0 fosters the implementation of technologies (including HMIS) into facilities. This leads to major advancement and the emergence of new trends in the HMI industry. Here’s the list of some of the most promising trends in human-machine interface development.

Remote monitoring

Remote monitoring is one of the hottest trends in HMI programming. It allows operators to control the equipment and monitor the status of processes without the need to be in the workplace.

With this functionality, controlling the performance of machinery by using portable devices (smartphones, tablets, laptops, etc.) may become a common practice in the nearest future.

Cloud-based HMI software

These days, the accessibility of data is more of a necessity than a nice-to-have option. Therefore, the data sync between the local human-machine interface and the cloud will allow accessing visualized information about the equipment status remotely.

Intuitive control panels

High performance and fast, intuitive interaction are hot trends in human-machine interface programming. A simple, uncluttered design and graphics of the control panels help optimize the user experience and improve productivity. By viewing only crucial data, the operators won’t get distracted and will address the problems more quickly and effectively.

Touch screens and mobile devices

The emergence of touch screens and smartphones has given a great push for the advancements of HMI technology. Instead of buttons and switches, the latest human-machine interface systems use multitouch technologies that allow controlling the machine by tapping or touching the physical screen.

Smartphones have become indispensable tools in our everyday lives. Thus, connecting HMIs with mobile phones was inevitable. The technology works either by using a mobile application or accessing a web-based human-machine interface system in the browser and provides users the ability to access controls instantly.

Let's discuss which IT outsourcing trends will change the industry.

Wearable devices

Wearable devices have boomed the technological market and quickly conquered the mindset of their consumers. So it is a no-brainer that the growing popularity of smartwatches and smart bracelets has also influenced the HMI industry.

The devices may be used to communicate with human-machine interfaces and display alerts about potential issues or even send signals to the equipment to make it perform specific actions.

Voice recognition

Voice recognition technology allows the software to interpret human voices. As a result, users can control the device through hands-free and intuitive interactions.

Voice-activated human-machine interface systems will provide operators the ability to use voice commands to control machinery and check critical metrics regarding its status.

Gesture recognition

Gesture recognition is one more promising technology that can transform the HMI industry. With advanced motion sensors that can perceive and decode movements, gesture HMIs will allow touchless control over machinery.

The gesture recognition technology can be implemented through the use of hand-tracking controllers, wired gloves, or depth-sensing cameras. Although the technology is quite complex, it will definitely make the interaction between humans and equipment quicker and smoother.

Final thoughts

The last few decades have brought a wide range of technological advancements into every aspect of our life. The human-machine interface systems are amongst the most widely used ways to automate the control over machines and equipment in a number of industries.

The implementation of HMI technology influences the operator and system performance directly. Providing enhanced situational awareness and intuitive control allows to make human-machine interaction smooth, improve the efficiency of the facility, decrease downtimes and ensure safety in the workplace.

If your company is looking for a reliable human-machine interface for your workplace or wants to learn more about the technology, our experts are always ready to help. At Jelvix, we specialize in designing innovative solutions that bridge communication gaps between humans and machines. Contact us to receive a free consultation that may help you figure out what exactly your business needs are.

Need a qualified team?

Access the talent pool to scale your team capacity.